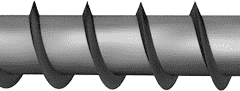

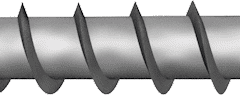

self Tapping screw

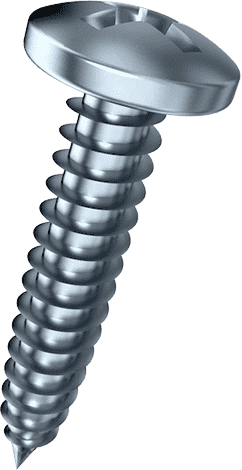

Pan Head Self Tapping Screw

|

Black Phosphated |

|---|---|

|

White Blue Zinc Plated |

|

Yellow Zinc Plated |

|

Nickel Plated |

|

Ruspert |

|---|---|

|

Dacromet |

|

Hot Dip Galvanized |

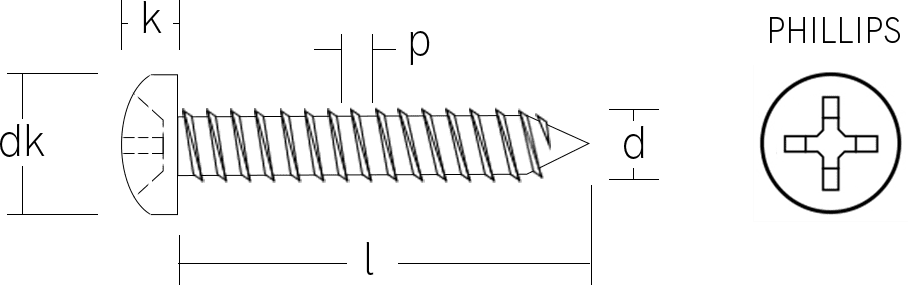

| d: M3.5-M4.8 l: 13mm-50mm dk:6.9-12.5 k:1.5-3.65 |

| Size | 3.5x | 3.9x | 4.2x | 4.8x |

|---|---|---|---|---|

| (mm) |

13

16 19 25 |

13

16 19 25 32 38 50 |

13

16 19 25 32 50 |

13

16 19 25 32 38 45 50 75 |

| #6x | #7x | #8x | #10x | |

|---|---|---|---|---|

| (inch) |

1/2"

5/8" 3/4" 1" |

1/2"

5/8" 3/4" 1" 1-1/4" 1-1/2" 2" |

1/2"

5/8" 3/4" 1" 1-1/4" 2" |

1/2"

5/8" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2" |

Color box

Color box White box

White box Brown box

Brown boxAbout delivery

For Pan head self tapping screw orders with a total order of less than 30 tons, if there are no special circumstances, we will ship within 20 days after ordering

Packaging details

1. We have several sizes of packing dimensions, can be 20kg or 25kg per carton.

2. For large orders, we can design specific sizes of boxes and cartons.

3. Normal Packing: 1000pcs/500pcs/250pcs per small box. then small boxes into cartons.

4. Can provide special packings as middle east clients requests.

Q: What is the MOQ for Pan head self tapping screws ?

A: Our screw MOQ is usually 1 ton per size.

Q: Can we print our own logo on packaging or Pan head self tapping screws?

A: Yes, packing and Pan head self tapping screws we can make according to your requirements.

Q: How long is the delivery time for Pan head self tapping screw?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your payment term?

A: Generally, 30% T/T in advance ,balance before shippment or against B/L copy.

Q: Are you trading company or Pan head self tapping screw manufacturer?

A: We are direct Pan head self tapping screw manufacturer, who owns production lines and workers. No need to worry about extra charges by the middle man or trader.

Pan Head Self Tapping Screw Manufacturer - High-Quality Fasteners for Industrial Applications

Welcome to SHIMAI HARDWARE, your trusted partner in providing premium quality fasteners. As a leading Pan Head Self Tapping Screw manufacturer, we are dedicated to offering superior products that meet the rigorous demands of various industries. Our screws are designed to provide reliable performance, exceptional durability, and optimal functionality in a wide range of applications.

What is a Pan Head Self Tapping Screw?

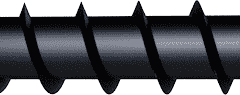

A Pan Head Self Tapping Screw is a type of fastener designed with a wide, rounded head and a sharp, cutting thread that enables it to create its own hole as it is driven into the material. This eliminates the need for pre-drilling, saving time and labor. These screws are commonly used in materials like metal, plastic, and wood, providing a secure and lasting hold.

Key Features and Benefits

1.Ease of Use: One of the primary advantages of Pan Head Self Tapping Screws is their ability to tap threads into the material directly, simplifying the assembly process.

2.Versatility: These screws are suitable for various materials and applications, making them a versatile choice for manufacturers and engineers.

3.Strong Hold: The design of the pan head provides a larger surface area for the screw to bear load, enhancing the strength and stability of the connection.

4.Corrosion Resistance: Many of our screws come with coatings such as zinc or stainless steel finishes, which provide excellent resistance to corrosion and extend the life of the fastener.

Applications of Pan Head Self Tapping Screws

Pan Head Self Tapping Screws are widely used in multiple sectors due to their versatility and reliability. Some common applications include:

Electronics and Electrical Appliances: Ensuring secure and stable assembly of components.

Automotive Industry: Used in various parts of vehicles for strong and durable connections.

Construction and Building: Essential for joining metal and plastic parts in building structures.

Furniture Manufacturing: Ideal for assembling different parts securely.

Why Choose SHIMAI HARDWARE?

At SHIMAI HARDWARE, we pride ourselves on our commitment to quality and customer satisfaction. Here are some reasons why our Pan Head Self Tapping Screws stand out in the market:

Precision Manufacturing: Our screws are manufactured with high precision to ensure consistent quality and performance.

Stringent Quality Control: Each batch of screws undergoes rigorous testing to meet international standards.

Custom Solutions: We offer customization options to meet specific requirements, including different sizes, materials, and finishes.

Competitive Pricing: We provide high-quality screws at competitive prices, ensuring value for money.

How to Choose the Right Pan Head Self Tapping Screw

Selecting the appropriate Pan Head Self Tapping Screw depends on several factors:

Material of the Screw: Choose a material that is compatible with the material you are fastening. For example, stainless steel screws are ideal for corrosive environments.

Size and Length: Ensure the screw length and diameter are suitable for the thickness of the material.

Thread Type: Different thread types are designed for different materials; coarse threads for wood and fine threads for metal.

Head Style: The pan head is ideal for applications where a flat, low-profile head is needed.

Conclusion

For robust, reliable, and high-quality Pan Head Self Tapping Screws, SHIMAI HARDWARE is your go-to manufacturer. Our screws are designed to meet the highest standards of performance and durability, making them the preferred choice for industrial applications worldwide. Contact us today to learn more about our products and how we can assist with your specific needs.

We are screw manufacturer, contact us for more information.

Reviews

There are no reviews yet.